Ultra-fine Powder Screening

Ultra Fine Ultrasonic Vibrating Sieve also known as:Ultrasonic Vibraitng Sieving,Ultrasonic Sieve Machine,It is widely used in laboratories, quality inspection rooms and other inspection departments to determine the particle size distribution of granules, powders, and preparations, as well as the determination and analysis of product impurity content and liquid solid content. The product has the characteristics of compact structure, low noise, high efficiency and accurate precision. It adopts a high-quality new type of power generator to generate multiple high-frequency vibrations to efficiently screen and measure materials. At the same time, different working hours can be realized through the electronic delay device according to different materials, so as to minimize the inspection error, ensure the consistency of sample analysis data, and make accurate judgments on product quality.

Contact

Contact

Online Consult

Online Consult

- Description

- Specifications

- Paper

- Video

Ultra Fine Ultrasonic Vibrating Sieve DHSF-U2 also known as:Ultrasonic Vibraitng Sieving,Ultrasonic Sieve Machine,It is widely used in laboratories, quality inspection rooms and other inspection departments to determine the particle size distribution of granules, powders, and preparations, as well as the determination and analysis of product impurity content and liquid solid content. The product has the characteristics of compact structure, low noise, high efficiency and accurate precision. It adopts a high-quality new type of power generator to generate multiple high-frequency vibrations to efficiently screen and measure materials. At the same time, different working hours can be realized through the electronic delay device according to different materials, so as to minimize the inspection error, ensure the consistency of sample analysis data, and make accurate judgments on product quality.

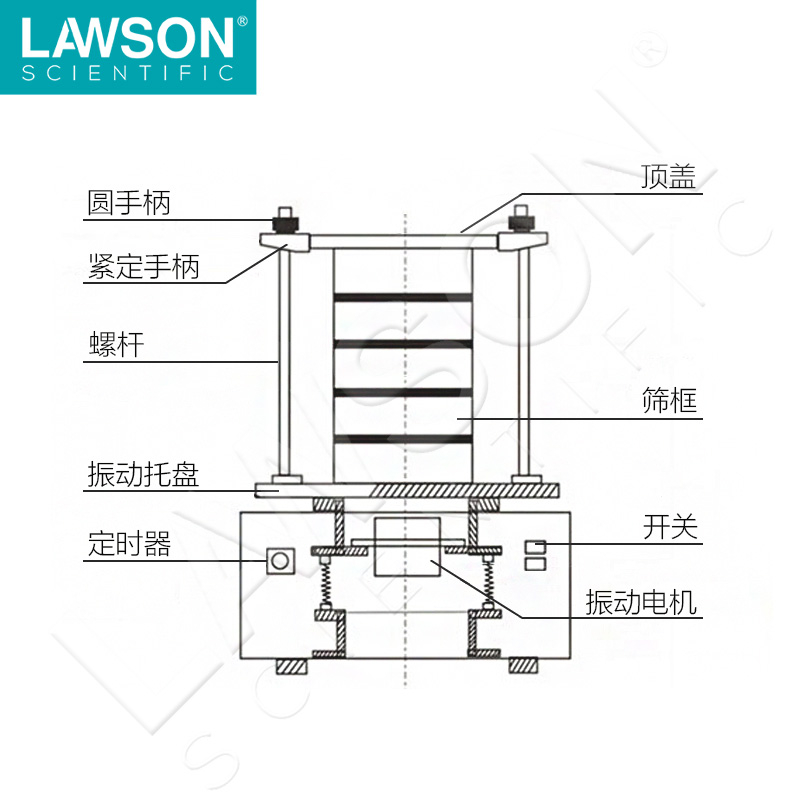

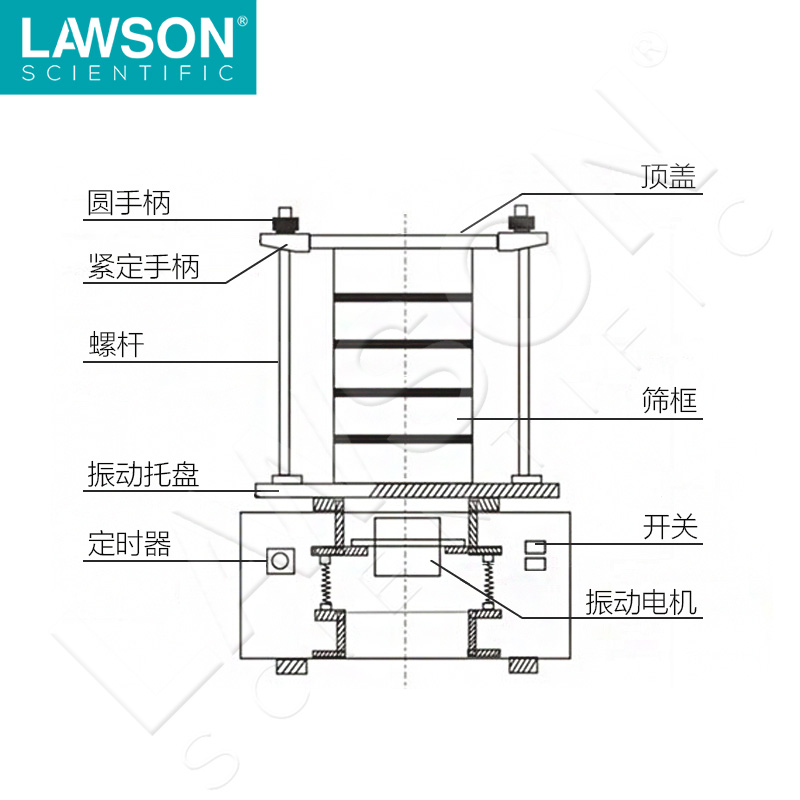

Structure of Mechanical Oscillating Screener

Structural Features of Mechanical Oscillating Screener

The product has the characteristics of compact structure, low noise, high efficiency and accurate precision. It adopts a new type of power generator of Xinzheng Machinery to generate multiple high-frequency vibrations to efficiently screen and measure materials, so it is also called inspection sieve. The structure of the test sieve is mainly divided into two parts: the body and the sieve. The screen part is designed and produced by our factory, and the screen part is the standard screen produced by the national military enterprise AVIC. One is the high-standard sieve used by scientific research institutions and national testing institutions. Industrial grade sieves with 100 mesh and coarse mesh are made of brass, mainly due to the good ductility of brass mesh, and 100 mesh and finer meshes are made of 304 stainless steel, that is, the wire woven mesh test screen mesh is made of national Standard GB/T6003.1-1997 production. The basic size of the mesh is 2.36mm-0.038mm, which conforms to the international standard ISO3310-1: 1990 R20/3, R20, R40/3 series, and the screen material is brass, tin bronze and stainless steel. 2.36um-100um is processed by nickel plating, which can not only improve the accuracy of the mesh, but also prevent the deformation of the mesh, which is strong, wear-resistant and durable.

1. The sieve (sieve grid) is easy to replace. This mechanical oscillating sieve uses a layer-by-layer sieve grid superimposed on the sieve tray, and uses a round handle, a fixed handle, a pressure head, a cover plate and other components to press the sieve grid tightly, and the sieve grid is easy to replace. Mesh material, just replace the sieve.

2. At the same time, different working hours can be realized through electronic delay devices according to different materials, so as to minimize inspection errors, ensure the consistency of sample analysis data, and make accurate judgments on product quality.

3. The vertical vibration motor produced by the motor department of our factory is used as the excitation source, with long service life and reliable quality.

4. The body part of the mechanical oscillating sieve can be designed as 304 stainless steel body or ordinary steel body (polishing, spraying, brushing anti-rust paint) according to user requirements.

5. The screen grid (screen tool) is designed for the national standard 304 stainless steel, which conforms to the national standard. Screens are classified into wire mesh, metal perforated plate, electroforming and other types according to the screen surface material. The sieve is produced according to the national standard GB/T6003.1-1997. In line with the international standard ISO3310-1: 1990. The mesh size of the perforated plate test sieve is 32mm-1mm; the mesh size of the woven mesh test sieve is 2.36mm-0.015mm; the mesh size of the electroforming test sieve is 0.50mm-0.005mm. The sieve frame, sieve cover and sieve bottom are made of high-quality stainless steel.

How to use the mechanical shaker:

1. Determine the standard sieve to be selected according to the inspected material and the corresponding standard.

Second, stack the standard sieves on the tray seat in order from large to small according to the aperture, and position the standard sieves by grooves or positioning screws.

Three, put the tested material into the top standard sieve, (or cover the standard sieve cover) and then press the standard sieve with the sieve head set on the wire column, and screw the wire column nut to compress the standard screen. (Note: Use the same force on both sides, and then use the locking screw to lock it.)

Fourth, put the timer switch in the corresponding required position, (pay attention to reading the timer description, the set time is different for different settings) and then turn on the power switch, the test sieve will start to work.

5. After the mechanical oscillating sieve stops working, unscrew the nut on the wire column, remove the sieve head, and carefully remove the standard sieve.

| Model | DHSF-U2 |

| standard sieve | 8 floors |

| Screen diameter | Φ300Φ200Φ100mm |

| Sieve particle size | 0.038-3mm |

| noise | ≤50db |

| Feeding amount (one-time) | ≤200g |

| amplitude | ≤5mm |

| Voltage | 220V |

| Rotating speed | 1420r/min |

| power | 0.125Kw |

| Total Weight | 25Kg |

| Dimensions | 360×300×736mm |

| host | 1 set |

| sieve frame | 8 floors |

| user's manual | 1 part |

| Warranty Card | 1 part |

| certificate | 1 part |

Scope of application

Laboratory in pharmaceutical, metallurgy, chemical, mineral processing, food and other industries

Notes