3D Rotary Vibrating Screen

DHSF-200 3D Rotary Vibrating Screen is a new generation of laboratory vibrating sieve. It adopts international leading technology and uses electromagnetic drive to produce three-dimensional throwing motion effect. It is equipped with analysis sieves of different specifications, which can meet the particle size classification and measurement of powders, particles, lumps and suspended solids. It has the advantages of high measurement accuracy, reproducibility of sieving results, and low noise. It is widely used in particle analysis in soil, pharmaceutical, metallurgy, mining, coal, grain and other industries. The screening results are efficient and reliable, ideal for scientific research and production, quality control and R&D.

Contact

Contact

Online Consult

Online Consult

- Description

- Specifications

- Paper

- Video

DHSF-200 3D Rotary Vibrating Screen is a new generation of laboratory vibrating sieve. It adopts international leading technology and uses electromagnetic drive to produce three-dimensional throwing motion effect. It is equipped with analysis sieves of different specifications, which can meet the particle size classification and measurement of powders, particles, lumps and suspended solids. It has the advantages of high measurement accuracy, reproducibility of sieving results, and low noise. It is widely used in particle analysis in soil, pharmaceutical, metallurgy, mining, coal, grain and other industries. The screening results are efficient and reliable, ideal for scientific research and production, quality control and R&D.

3D Rotary Vibrating Screen working principle

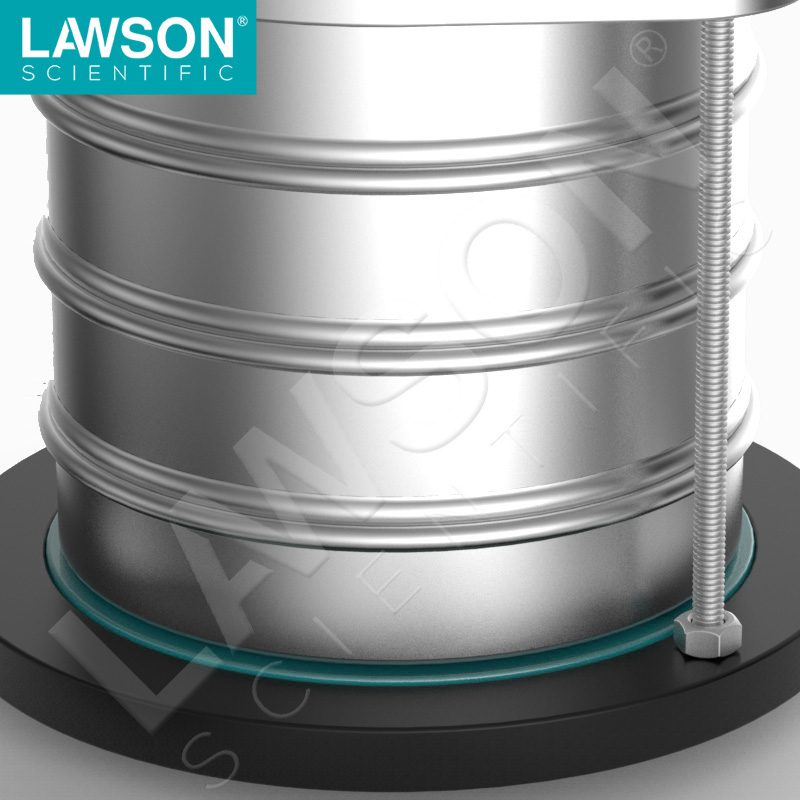

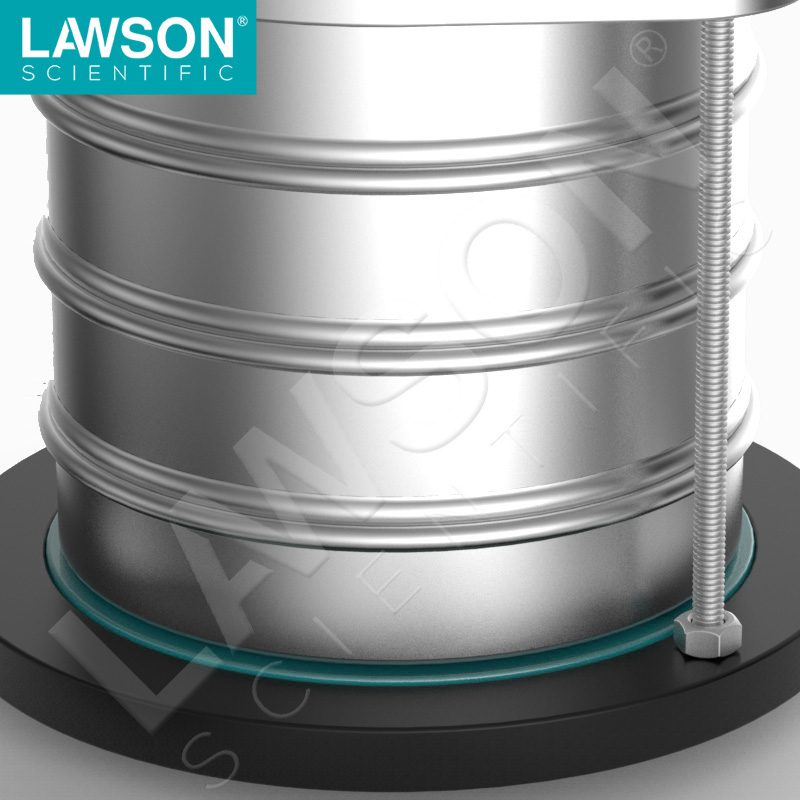

DHSF-200 3D Rotary Vibrating Screen The main body is electronically controlled by an electromagnet with a vibration transmission component on it. This driving component can produce a three-dimensional throwing motion effect, and the sample can be evenly distributed on the entire screen surface, which can be filtered layer by layer faster and more effectively, so as to obtain extremely high The screening accuracy also brings high load, quiet operation and high efficiency, resulting in higher separation accuracy in a shorter time, and can ensure the repeatability of screening results.

Technical Features of Mechanical Oscillating Screener

l The three-dimensional throwing motion mode ensures that the sample is evenly scattered on the entire mesh surface

Common particle size and micron comparison table

| Number of meshes | Micron | Number of meshes | Micron |

| 20 | 850 | 120 | 125 |

| 25 | 710 | 140 | 106 |

| 30 | 600 | 170 | 90 |

| 35 | 500 | 200 | 75 |

| 40 | 425 | 230 | 63 |

| 45 | 355 | 270 | 53 |

| 50 | 300 | 325 | 45 |

| 60 | 250 | 400 | 38 |

| 70 | 212 | 450 | 32 |

| 80 | 180 | 500 | 25 |

| 100 | 150 | 635 | 20 |

|

Model |

DHSF-200 |

| Sample characteristics | Powders, loose granules, suspensions |

| form of exercise |

three-dimensional throwing motion |

| Time Display | 1-99min |

| Measuring range | 20μm-30mm |

| Vibration amplitude | 0—3mm continuous adjustment |

| dry sieve, wet sieve | can be |

| intermittent operation | 0-99s |

| maximum load | 3kg |

| Maximum series |

Level 9 |

| Screen material | stainless steel, nylon |

| Analytical Sieve Diameter | 100 / 150 / 200 / 300 mm |

| Total Weight | 25Kg |

| Power data | AC 220V±10% 50Hz |

| host | 1 set |

| sieve frame | 8 floors |

| user's manual | 1 part |

| Warranty Card | 1 part |

| certificate | 1 part |

Scope of application

注意事项