Technical

Commonly used dispersion methods for graphene preparation

1. Micro-mechanical stripping method

Use tape to peel the graphene flakes directly from the larger crystals and repeat the process.

Using a material to rub against pyrolytic graphite that has expanded or introduced defects, the surface of bulk graphite will produce flake-like crystals, and the flake-like crystals contain a single layer Graphene.

Disadvantages: Graphene has low yield, small area, difficult to precisely control the size, low efficiency, and cannot be prepared on a large scale.

2.Chemical Vapor Deposition

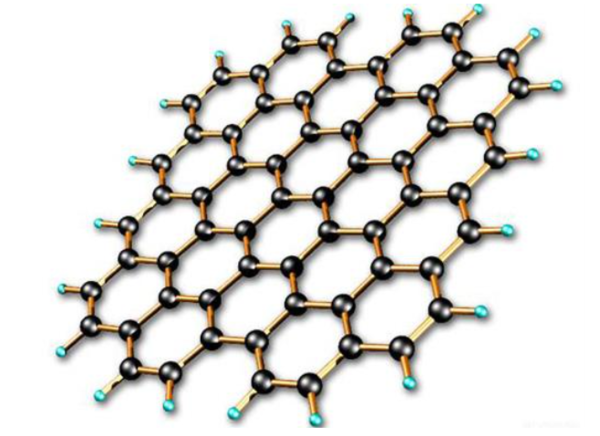

Pour one or more carbon-containing gaseous substances (usually low-carbon organic gas) into the vacuum reactor, and the carbon-containing gas is decomposed and carbonized by high temperature (usually low-carbon organic gas), the process of growing a carbon element on the surface of the substrate.

Disadvantages: The hexagonal honeycomb crystal structure of graphene cannot be completely graphitized, the quality is not as good as that of the microcomputer exfoliation method, and the high cost The cost and strict equipment requirements limit the large-scale production of graphene, and the addition of catalysts reduces the purity of graphene.

3. Epitaxial growth method

One is to remove Si by heating single crystal 6H-SiC, thereby epitaxially growing graphene on the surface of SiC crystal. The graphene is in contact with the Si layer, and the conductivity of this graphene is affected by the substrate; the other is to use the trace carbon component in the metal single crystal, and through high temperature annealing under ultra-high vacuum, the carbon element in the metal is on the surface of the metal single crystal. Graphene is precipitated.

Disadvantages: The thickness of the graphene film is uneven and difficult to control, and the resulting graphene sticks tightly to the substrate and is difficult to peel off , which will affect the properties of graphene. At the same time, it needs to grow under ultra-vacuum and high temperature conditions, the conditions are extremely harsh, and the equipment requirements are high, and it is impossible to achieve large-scale and controllable preparation of graphene.

4. Graphite oxide reduction method

Graphene oxide is generally obtained by oxidation of graphite by strong acid. There are three main methods for preparing graphite oxide: Brodie method, Staudenmaier method and Hummers method. The Hummers method requires the addition of ultrasound to disperse graphene.

Features: Hummers method graphene dispersion: The method is simple, time-consuming, It has a large processing capacity, is safe and pollution-free, and is currently the most commonly used one.

5. Ultrasound-assisted method

Ultrasonic graphene dispersion system adopts ultrasonic-assisted Hummers method to prepare graphene oxide. It uses liquid as medium and adds high-frequency ultrasonic vibration to the liquid. Since ultrasound is a mechanical wave, it is not absorbed by molecules and causes vibrational motion of molecules during propagation. Under the cavitation effect, that is, under the additional effects of high temperature, high pressure, micro-jet, and strong vibration, the distance between molecules increases their average distance due to vibration, which eventually leads to molecular breakage. The interlayer spacing of graphite oxide can be improved more effectively, and with the increase of ultrasonic power, the interlayer spacing of the obtained graphite oxide tends to expand.

The instantaneous pressure released by the ultrasonic wave destroys the van der Waals forces between graphene layers, making graphene less likely to agglomerate together. Graphite oxide with a large interlayer spacing is not only conducive to the intercalation of other molecules, atoms, etc. into the interlayer to form a graphite oxide intercalated composite material, but also easy to be exfoliated into a single-layer graphite oxide, which lays the foundation for the further preparation of single-layer graphene.

--------------------------------------------------------- -------------

If you want to know more, please call for details.

+86 574 8908 5816 +86 186 5743 5285

Or swipe the QR code below: